Gas-reciprocating power plants

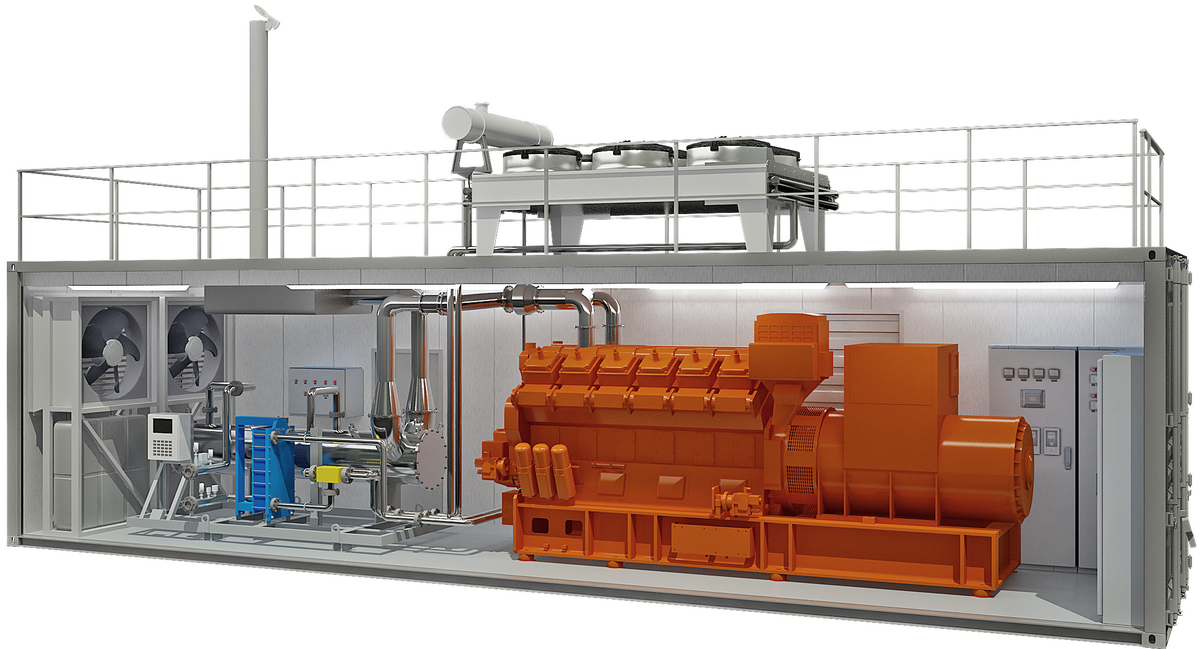

PiterEnergoMash designs, supplies, mounts and commissions the power plants based on gas-reciprocating units with a capacity of 250 kVA to 52.000 kVA in container and block-modular implementation. We provide gas-reciprocating power plants packaged in standard 20- and 40-foot containers produced by our company. The choice of container is made is based on power of the station undergoing packaging and the size of the main gas-reciprocating unit. All items of equipment for the stations are provided with quick disconnect joints, which makes it easy and timesaving to mount and disassemble the components of the system in case of repairing or replacement. All gas-reciprocating power plants packaged by PiterEnergoMash are equipped with security and fire alarm systems and access monitoring and control systems integrated into containers.

Gas-reciprocating power plants have a simple and reliable design, service-tested thought decades of operating in various climatic environment. Electrical efficiency of gas-reciprocating power plants is considered high, in contrast, to efficiency of turbines and microturbines, and at operating on quality natural gas equals approximately 39-44%, which means that for generating the same amount of electric power, gas-reciprocating power plants consume one-third less natural gas compared with the turbines.

PiterEnergoMash designs gas-reciprocating power plants, which, in extended version, are capable of operating in cogeneration mode, i.e. operating as a thermal power plant. The exhaust gas temperature at the exit of the power machine of the gas-reciprocating power plant equals approximately 390 ± 10°C. Such temperature allows to obtain easily virtually free thermal power in cogeneration mode.

The electricity output and thermal power ratio is 1: 1, i.e. it is possible to get 1 MW of thermal power for 1 MW of installed electric power.

The output ratio of saturated steam for gas-reciprocating power plant equals 0.5-0.7. Steam can be used for production purposes.

In order to meet the environmental requirements the company installs catalysers of exhaust gas in the gas-reciprocating power plants, though the release harmful emissions of gas-reciprocating power plants is initially very low which is due to the fact that, being the basic fuel, gas releases virtually no harmful substances at combustion. The height of the stack for gas-reciprocating power plants is determined by the content level of maximum permissible concentration in the environment and by the level of harmful constituents.

The average level of noise produced by a gas-reciprocating units equals 75-78 dB. The gas-reciprocating units produces some vibrations while operating which sometimes requires the installation of special shock mounts.