Automated processes control systems for electric substations

An automated process control system is a set of hardware and software designed to automate control of process equipment. Automated control management should be implemented mainly in unattended remote electric substations. The experts of PiterEnergoMash implement various designs of automated process control systems providing the use of either local or remote automated process control system.

As part of automated process control system electric substation provides the following functions:

Operational management. Collecting and primary processing of discrete and analog information,forming, renewing, updating of databases, registration of accidents and transients, fixating of fact and the time of control commands issuing, metering of electric power supplied to consumers , transferred to adjacent power systems or received from them, displaying and documenting of information for operating personnel, monitoring the current values of mode parameters, detecting duration of permissible overload of transformers and other equipment, controlling of duration of equipment operating at extra load (in case of overload), voltage quality control, monitoring of operating of transformers and other equipment, recording equipment status, defining resource of transformers (by isolation and electrodynamic effects) and switching equipment.

Operational management. Collecting and primary processing of discrete and analog information,forming, renewing, updating of databases, registration of accidents and transients, fixating of fact and the time of control commands issuing, metering of electric power supplied to consumers , transferred to adjacent power systems or received from them, displaying and documenting of information for operating personnel, monitoring the current values of mode parameters, detecting duration of permissible overload of transformers and other equipment, controlling of duration of equipment operating at extra load (in case of overload), voltage quality control, monitoring of operating of transformers and other equipment, recording equipment status, defining resource of transformers (by isolation and electrodynamic effects) and switching equipment.Automatic control provides controlling of voltage and reactive power, controlling an operating transformer bank (optimization a number of operating transformers on bases of minimal loss of active power), load control in emergency condition, adaptive automatic reclosing and automatic transfer switch.Automatic control functions, at normal operating condition, include voltage regulation at electric substation busbars by changing the transformation ratio of transformers, switching on and off of capacitors, operational switching to a given program, locking of disconnectors, synchronizing, disabling one of parallel- operating transformers to reduce total power loss at small loads, automated reading of electricity meters.

Relay protection provides relay protection of all elements of an electric substation, diagnosis and testing of relay protection and automation, adaptation of relay protection, analysis of relay protection action to alarms, breaker failure protection.

Monitoring and measuring function provides determining resource of transformer on-load tap chargers, controlling insulation of high -voltage condition, analysis of emergency situations, monitoring and controlling of power consumption, automatic generating of routine switching forms, monitoring state of operated current network, controlling and optimization of the compressor unit and an air supply system of breakers, controlling cooling of transformers, controlling the state of automatic fire extinguishing, controlling switching equipment, the determining the distance to a fault on an electric power transmission line, automatic keeping of daily records, the forming of telemetry and telesignals and transfering them to dispatching stations of superordinate control levels, implementing of commands of remote control of switching devices and controls, arranging of required communication and control channels with dispatching stations and emergency crews.

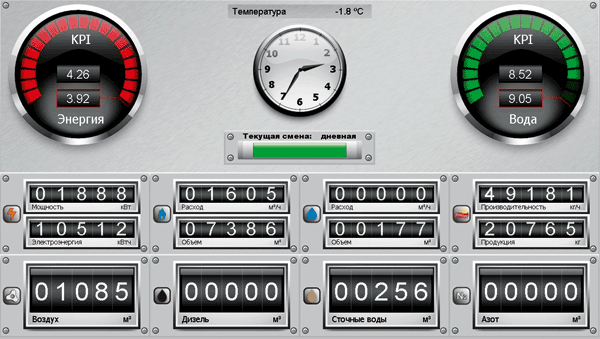

In contrast to a dispatch control system, an automated process control system is capable of controlling all protection parameters, not just a switch. It is obvious that an emergency or a contingency response of an automated process control system will incomparably faster. A dialog system of an automated process control system must provide an interface, intuitive for various categories of users, such as the operational personnel (the most simple communication language, close to natural), experts in the field of relay protection and emergency control, conducting setting, testing and changing of settings (more complex, specialized communication language), computer experts (the most complex language).

In contrast to a dispatch control system, an automated process control system is capable of controlling all protection parameters, not just a switch. It is obvious that an emergency or a contingency response of an automated process control system will incomparably faster. A dialog system of an automated process control system must provide an interface, intuitive for various categories of users, such as the operational personnel (the most simple communication language, close to natural), experts in the field of relay protection and emergency control, conducting setting, testing and changing of settings (more complex, specialized communication language), computer experts (the most complex language).Taking into account how complex and demanding various control functions are, designing of automated process control system for electric substations is usually carried out in stages, starting with the less complex and demanding: operating control, automatic control and relay protection